Electrical safety audit in Bareilly

Product Details:

Product Description

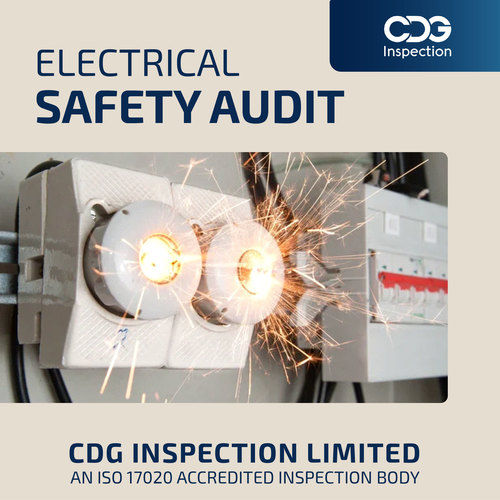

CIL Provides Accredited Electrical Safety Audit Services in Bareilly, Uttar Pradesh, India. CIL is an ISO 17020 accredited inspection body for Electrical safety audit and Electrical safety inspection. Electricity can kill or severely injure people and cause damage to property. However, employers can take simple precautions when working with or near electricity and electrical equipment to significantly reduce the risk of injury to themselves, their workers and others around them. This section provides a summary of those precautions. What are the hazards, The main hazards of working with electricity are, Electric shock and burns from contact with live parts, injury from exposure to arcing, fire from faulty electrical equipment or installations, explosion caused by unsuitable electrical apparatus or static electricity igniting flammable vapours or dusts, for example in a spray paint booth. Electrics hocks can also lead to other types of injury, for example by causing a fall from ladders or scaffolds etc. What should employers do, Employers must make sure that the electrical installation and the electrical equipment is, Suitable for its intended use and the conditions in which it is operated, only used for its intended purpose. In wet surroundings, unsuitable equipment can become live and make its surroundings live too. Fuses, circuit breakers and other devices must be correctly rated for the circuit they protect. Isolators and fuse box cases should be kept closed and, if possible, locked. Cables, plugs, sockets and fittings must be robust enough and adequately protected for the working environment. Employers must ensure that machinery has an accessible switch or isolator to cut off the power quickly in an emergency. Maintenance So far as reasonably practicable employers must make sure that electrical equipment and installations are maintained to prevent danger. Users of electrical equipment, including portable appliances, should carry out visual checks. Employers and workers must remove the equipment from use immediately and check it, repair it or replace it if, the plug or connector is damaged, the cable has been repaired with tape, is not secure, or internal wires are visible etc. burn marks or stains are present (suggesting overheating). Repairs should only be carried out by a competent person (someone who has the necessary skills, knowledge and experience to carry out the work safely). It is good practice if employers arrange for more frequent checks for items more likely to become damaged (e.g. portable electrical tools and equipment that is regularly moved, or used frequently or in arduous environments). Less frequent checks are needed for equipment less likely to become damaged (e.g. desktop computers etc.) Visual checks are not usually necessary for small, battery powered items, or for equipment that works from a mains powered adaptor (laptops or cordless phones etc.). However, the mains powered adaptor for such equipment should be visually checked. Employers must consider whether electrical equipment, including portable appliances, should be more formally inspected or tested by a competent person thinking also about the intervals at which this should be done. Arrangements should be made for inspecting and testing fixed wiring installations, i.e. the circuits from the meter and consumer unit supplying light switches, sockets, wired in equipment(e.g. cookers, hairdryers) etc., to be carried out regularly so there is little chance of deterioration leading to danger. This work must normally be carried out by a competent person, usually an electrician.