Electrical Safety Inspection in Delhi

Product Details:

Product Description

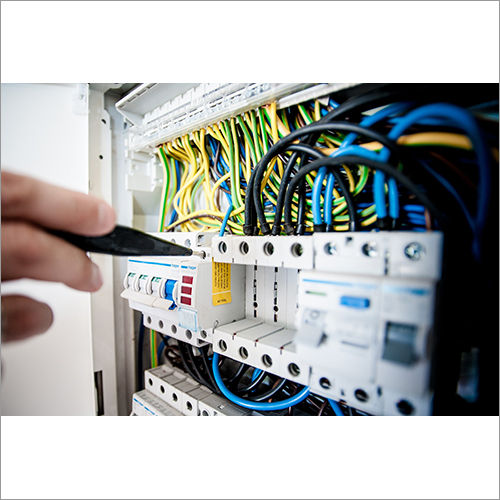

Having your electrical wiring inspected is one of the most important things to keep your factory safe from electrical hazards. You do not want to risk the lives of your loved ones, nor getting your property damaged due to electrical fires. Therefore, electrical safety should be atop priority in your factory. A proper electrical safety inspection will, Identify electrical wiring and components that may have degraded over time. Reveal if any electrical circuits are overloaded. Reveal if any lack of earthing. Identify any defective wiring or other mistakes made by non certified electrician. Spot oversized fuses or breakers that may cause an electrical fire hazard. Find any potential electric shock risks. When To Do Factory Electrical Safety Inspection, When purchasing a factory. It is better to ensure that your new factory is electrically safe before moving in. If your factory is more than25 years old and has not had an electrical inspection. If you have had a major renovation to your factory. If you observe an electrical appliance that is operating erratically, especially if it is much older. Periodic safety checks are also important and should be carried out every 10 years or while adding a new appliance. Factory Electrical Safety Inspection Checklist, All light fixtures, sockets, switches are in good condition and working. All wires are in good condition without any signs of deterioration, wear and tear. All circuit breakers, RCDs etc. are operating properly and fuse elements are appropriately installed. Suitability of all switchgear (MCBs, RCDs etc).Proper grouping and labelling inside the distribution panel. Earthing or grounding system is proper. Wiring method is up to date to ensure that it is suitable for current use. All wires of a circuit are grouped together. Proper insulation of electrical system near wet and damp locations. Wires or sockets are not being overloaded. Reducing the necessity of extension cords by adding permanent fittings if required. This is a general checklist while inspecting a factory electrical system. Adding to these, Portable Appliance Testing (PAT) should also be carried out periodically. This testing includes examination of electrical appliances and equipment. Visual examination, earth continuity testing, insulation test between current carrying parts and the outside metal etc. tests are carried out in PAT testing by a certified electrician or someone who has sound knowledge in electrical testing. Portable Appliance Testers for carrying out this testing can be available on rent or for buying. A certified professional electrician will inspect thoroughly to ensure the safety. It is important to call only a licensed electrician for safety inspection or for any major electrical work. You may be able to easily find a licensed electrician in your local area by searching on the internet. For example, these electricians in CDG provide electrical safety inspection and recommend you what can be done based on their inspection. Electrical safety inspection is must for every factory to ensure safety from electrical hazards.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+